Quality level is cultivated

in systems development for aviation engines

Problems with aircraft engines in-flight are entirely unacceptable. For a safe flight, it is necessary to carry out various tests such as high-precision measurement, high-speed transient analysis, etc., and to properly and surely evaluate its function on the ground before the flight.

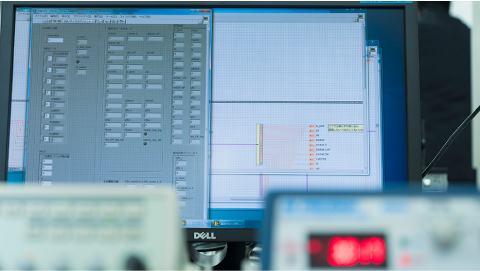

Systems that accurately execute these various tests for flight safety are measurement and control systems for aircraft engines. Cell Tech develops and manufactures software that requires high reliability. We are developing these systems with the aim of improving the reliability of software in various fields by making use of this development method for other software development.

systems for aircraft engines

Cell Tech's primary developed product, which implements many types of tests on aircraft engines. We are also developing automatic operation, database, and monitoring systems. Stable, Linux-based measurement and control systems.

measurement support system

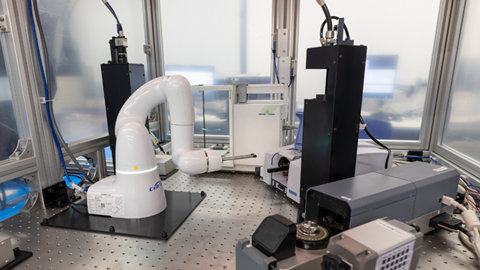

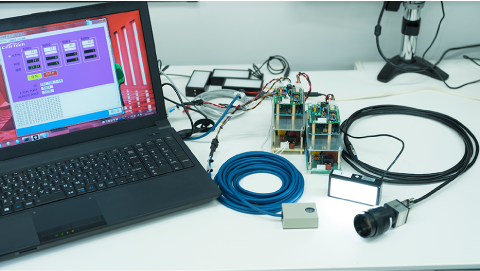

A system with an AI image processing system that determines the accurate placement of minute workpieces and collaborative robots that support measurement, cleaning, and inspection.

Systems that acquires and analyzes images at high speeds while controlling the camera position and light intensity that matches the movement of the subject.

Systems that download the engine data acquired during the flight after landing of the aircraft and analyzes various data in preparation for the next flight.

Thrust calibration control systems by mobile terminals that use a wireless LAN. These systems simplify configuration troubles and on-site work.

application

- • Wireless environmental monitoring systems

(industrial effluent ion concentration monitoring and control equipment) - • Closed-loop simulations

- • Real-time simulators for component development

- • Binary control equipment modeling and control systems

- • Binary control equipment modeling and control systems